Nylon cable ties are everywhere in our daily lives and industrial settings—securing wires in homes, organizing cables in offices, and even fastening components in automotive and aerospace fields. But have you ever wondered how these small, versatile tools came to be, what makes them so reliable, and how to choose the right one? This article uncovers the secrets behind nylon cable ties, from their history and production process to top brands, helping you make informed buying decisions.

A Brief History of Nylon Cable Ties

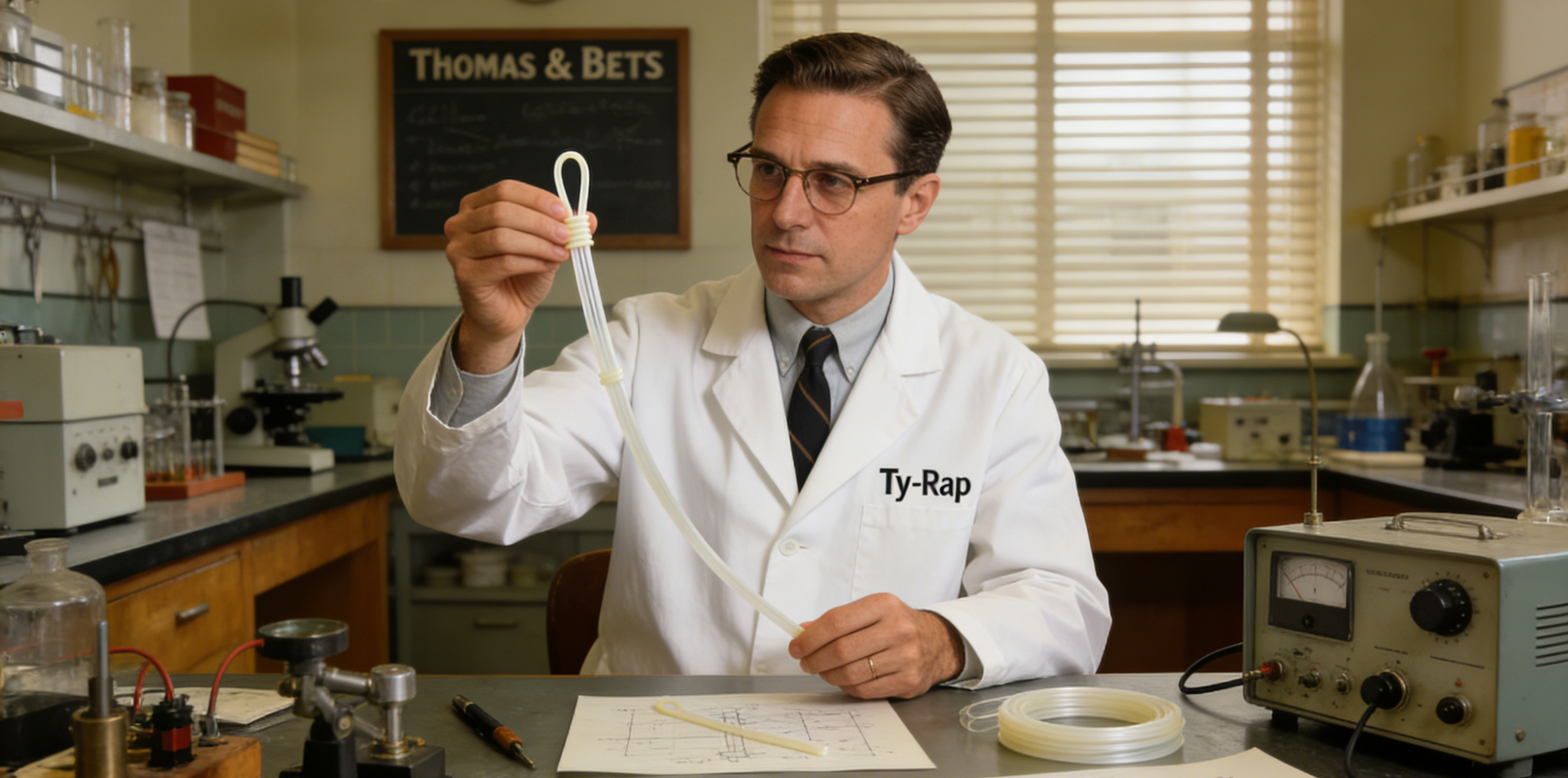

The story of nylon cable ties dates back to the 1950s, a time of rapid industrialization and innovation. Developed by Thomas & Betts, a leading electrical components manufacturer, the first nylon cable tie—known as the “Ty-Rap”—was created to solve a specific problem: efficiently securing wires in aircraft. Before nylon cable ties, workers relied on cumbersome methods like string, tape, or metal clips, which were time-consuming, less durable, and often failed under harsh conditions.

Nylon, a synthetic polymer invented by DuPont in the 1930s, was the perfect material for this new fastener. It offered exceptional strength, flexibility, resistance to chemicals and extreme temperatures, and was lightweight—all essential qualities for aerospace applications. As the benefits of nylon cable ties became apparent, their use expanded beyond aviation to construction, electronics, automotive, and household applications, becoming an indispensable tool worldwide.

The Production Process: What Makes Quality Nylon Cable Ties?

Understanding the production process of nylon cable ties helps buyers distinguish high-quality products from inferior ones. Here’s a simplified breakdown of the key steps:

1. Material Selection

The foundation of a reliable nylon cable tie is high-grade nylon resin, typically Nylon 6 or Nylon 66. These materials are chosen for their tensile strength, impact resistance, and ability to withstand UV rays and moisture. Inferior ties often use recycled or low-grade nylon, which compromises durability and load capacity.

2. Injection Molding

Injection molding is the primary manufacturing method. The nylon resin is melted at high temperatures (around 250–270°C) and injected into precision molds under high pressure. The molds are designed to create the tie’s shape, including the head (with a locking mechanism) and the flexible strap with serrations. This step requires strict temperature and pressure control to ensure consistent quality.

3. Cooling and Demolding

After injection, the molds are cooled rapidly to solidify the nylon. Once cooled, the molds open, and the finished nylon cable ties are ejected. Any excess material (flash) is trimmed off to ensure a clean, smooth finish.

4. Quality Control

High-quality manufacturers conduct rigorous quality checks, including testing tensile strength (how much force the tie can withstand before breaking), checking the locking mechanism for reliability, and inspecting for defects like cracks or uneven surfaces. This ensures that each nylon cable tie meets industry standards and performs as expected.

Top Mainstream Brands of Nylon Cable Ties

When buying nylon cable ties, choosing a reputable brand is key to ensuring quality and performance. Here are some of the most trusted names in the market:

1. Thomas & Betts (Ty-Rap)

As the inventor of the nylon cable tie, Thomas & Betts (now part of ABB) is synonymous with quality. Their Ty-Rap series offers a wide range of sizes and types, including standard, heavy-duty, UV-resistant, and heat-resistant options, suitable for industrial and commercial applications.

2. Panduit

Panduit is a global leader in electrical and network infrastructure solutions. Their nylon cable ties are known for their precision engineering and durability, with products designed for specific industries like data centers, automotive, and renewable energy.

3. 3M

3M’s nylon cable ties combine the brand’s expertise in adhesive and material science with reliable fastening solutions. They offer versatile options, including releasable ties (for reusability) and color-coded ties (for easy organization), popular among both professionals and DIY enthusiasts.

4. ACCORY Nylon Cable Ties

For buyers seeking a balance of quality and affordability, ACCORY’s nylon cable ties stand out. ACCORY’s ties offer excellent tensile strength and UV resistance, making them suitable for both indoor and outdoor use. The series includes standard, heavy-duty, and releasable options in various sizes, catering to home organization, automotive repairs, and small-scale industrial needs. With strict quality control measures, ACCORY ensures that each tie delivers consistent performance without compromising on reliability.

Key Tips for Choosing the Right Nylon Cable Ties

To meet your specific needs, consider these factors when selecting nylon cable ties:

- Material: Opt for Nylon 66 for better heat and UV resistance, especially for outdoor use.

- Size: Choose the length and width based on the items you’re securing—longer ties for larger bundles, wider ties for heavier loads.

- Type: Releasable ties for temporary fastening, heavy-duty ties for industrial applications, and color-coded ties for easy organization.

- Brand Reputation: Stick to trusted brands to avoid inferior products that may break or fail.

Conclusion

Nylon cable ties may seem simple, but their invention revolutionized fastening solutions across industries. From their aerospace origins to their widespread use today, their reliability stems from careful material selection and precision manufacturing. By understanding their history, production process, and top brands—you can choose the perfect tie for your needs. Whether for home, office, or industrial use, a quality nylon cable tie is a small but essential tool that simplifies organization and ensures safety.

Post time: Dec-20-2025