Understanding the Role of Cable Seals

Cable seals are physical locking devices used to secure the doors of shipping containers, trailers, and other cargo transport units. They provide a visible, single-use indicator of unauthorized access. Unlike simple bolt seals, a high-quality cable seal combines flexibility with immense tensile strength, allowing it to secure doors of varying gaps and alignments while resisting cutting, sawing, and pulling attacks. Their core purpose is deterrence and providing clear evidence of tampering.

A Brief History: From Lead to Advanced Composites

The history of tamper-evident seals is long, beginning with simple lead and wire seals pressed with a unique mark. The modern era of cable seals began with the need for more durable, weather-resistant, and secure options for intermodal shipping. Early versions used basic steel cables and simple locking mechanisms. The real advancement came with the integration of high-strength engineering plastics and advanced metallurgy, leading to today’s designs that are extremely resistant against tampering while being easier to inspect and handle.

Key Features of a Modern, High-Security Cable Seal

When evaluating cable seals, several design and material factors directly impact their effectiveness in the field:

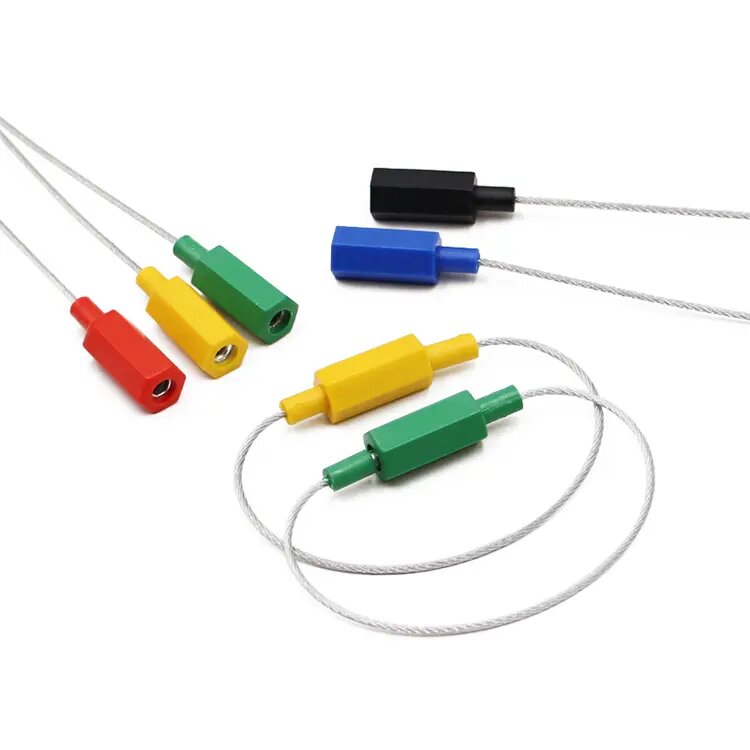

Robust Construction: Look for a seal that uses a high-impact ABS material for the body. This plastic coating is tough and won’t break easily from impact or cold temperatures, but it is designed to crack or show clear stress marks if manipulated, providing that essential evidence of tampering.

Advanced Locking Mechanism: The heart of the seal’s security lies in its lock. A mechanism made from powder metallurgy material offers far greater resistance to picking, prying, and crushing compared to standard metals. This, combined with a self-locking mechanism that is petroleum and sunlight resistant, ensures reliable performance in diverse environmental conditions.

Permanent Assembly & Tamper-Evident Design: In a well-constructed seal, one end of the cable is permanently secured into the locking body, preventing a common attack method of disassembling the seal intact. The principle is straightforward: removal only with a cable cutter. Any other attempt should leave obvious damage.

Production Process: Engineering for Trust

Manufacturing a reliable cable seal is a precise process. It starts with forming a galvanized steel wire rope for high tensile strength and corrosion resistance. The hexagonal body is typically moulded with high-impact ABS material in a process that often encapsulates the cable end permanently. The most critical component, the locking mechanism, is created using powder metallurgy casting, a technique that allows for complex, hardened metal parts with excellent wear and tamper resistance. Each seal is designed as a fixed closure cable seal, meaning it is a single, inseparable unit upon locking.

The Bullet Polyhex Design: A Practical Security Solution

The Bullet Polyhex Container Cable Seal incorporates these modern security principles into a practical format. Its distinctive hexagonal body offers greater surface area for clear, stamped identification numbers. Constructed as a fixed length cable seal with a hexagonal body, using ABS plastic and powder metallurgy casting, it is built for the rigors of transport. The steel cable and robust plastic casting make it suitable for trailers, truck doors, and roller containers. Its design emphasizes that dual promise: being extremely resistant against tampering yet clearly showing any attempt to breach it.

Choosing the Right Seal for Your Operation

For logistics managers, security personnel, and business owners, selecting the right seal is a key part of the supply chain integrity plan. The ideal cable seal offers a balance of physical strength, environmental resilience, and unambiguous tamper evidence. It should integrate seamlessly with your tracking and inspection protocols.

A product like the Bullet Polyhex represents the current standard in accessible, high-performance security. By choosing a seal with advanced material science behind its powder metallurgy locking mechanism and durable ABS coating, you invest in a solution that protects your assets and provides peace of mind. Always remember that the final step of the process—removal only with a cable cutter—is the ultimate test of the seal’s integrity and your security system’s effectiveness.

Post time: Jan-06-2026